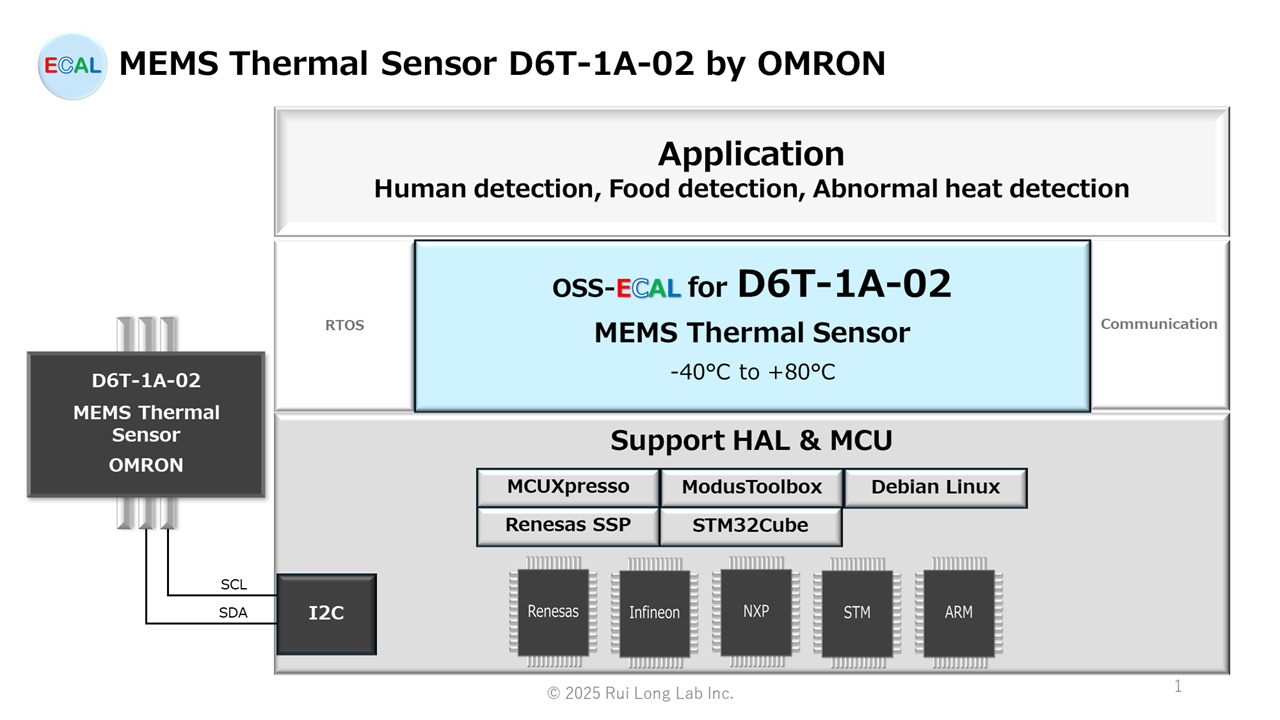

This is an overview of the D6T-1A-02 and the OSS-ECAL offering for the D6T-1A-02. The D6T-1A-02 is a MEMS Thermal Sensor (-40°C to +80°C) for industrial use manufactured by OMRON.

MCU interface : I2C

CAUTION:Please be sure to refer to the latest version of the Datasheet prior to actual design.

D6T-1A-02

Overview

MEMS non-contact temperature sensors measure the surface temperature of an object. The D6T-44L-06 has 16 channels, the D6T-8L-09 has 8 channels per row, the D6T-1A-01/-02 has 1 channel, and the D6T-32L-06 has 1024 channels, 32 x 32. The D6T-32L-06 is equipped with a 1024-channel sensor chip (32×32). The D6T-32L-06 is equipped with a 1024-channel sensor chip (32 x 32 vertically and horizontally). The D6T-32L-06 is equipped with a 1024-channel sensor chip, 32 x 32 (vertical and horizontal), and the D6T-1A-01/-02 is equipped with a single channel.

Our MEMS non-contact temperature sensor can be used as a human detection sensor to solve the shortcomings of conventional pyroelectric sensors for human detection. The pyroelectric sensor detects infrared radiation changes. Pyroelectric sensors can detect human motion, but they lose their measurement signal when the person is stationary, due to the principle of detecting the changing components of infrared rays. However, pyroelectric sensors lose their measurement signal when the person is stationary. On the other hand, a non-contact temperature sensor can detect a person’s movement when the person is stationary, In contrast, a non-contact temperature sensor does not lose its measurement signal even when the sensor is stationary.

MEMS non-contact temperature sensors have a defined sensitivity characteristic due to optically designed silicon lenses. Our non-contact temperature sensors, like most sensors, have a range angle of 50% of the maximum sensitivity. In our non-contact temperature sensors, as in general sensors, the area angle at which 50% of the maximum sensitivity is achieved is described as FOV (Field of View). The FOV (Field of View) of our non-contact temperature sensors, like most sensors, is described as the area angle at which 50% of the maximum sensitivity is achieved.

The sensitive area is wider than the FOV specification width. If the size of the object to be measured is smaller than the sensitive area, the effect of background temperatures other than the object will be included. If the size of the object to be measured is smaller than the sensitive area, the effect of background temperatures other than the object will be included. Our non-contact temperature sensors use a reference heat source (blackbody furnace) to compensate for temperature measurements. Note that differences in emissivity due to the material of the object to be measured, surface shape, occupancy in the sensitive area, etc. will affect the measured value. Please note that differences in emissivity due to the material of the object to be measured, the shape of the surface, and occupancy in the sensitive area can affect the measured value.

As the distance increases, the area to be observed (FOV) increases, and the area occupied by the object (person) in the FOV. The percentage of area occupied by the object (person) in the FOV decreases with distance. Therefore, as the distance increases, the percentage of the measured value (influence) increases. The background temperature is larger than the object (person) temperature. In other words, in order to measure temperature correctly In other words, to measure temperature correctly, the object must be sufficiently larger than the FOV area.

When a MEMS non-contact temperature sensor is used as a human detection sensor, a simple determination based on temperature values alone is limited to short distance applications. If MEMS non-contact temperature sensors are used as human detection sensors, simple determination based on temperature values alone is limited to use in short distance applications. In order to increase the detection distance, it is necessary to improve the detection distance by software processing based on the temporal change, the location of the heat source, and human behavior information. To increase the detection distance, it is necessary to improve the accuracy of judgment by software processing based on information such as temporal changes, location of the heat source, and human behavior. The software processing is required to improve the accuracy of judgment.

Application

- Human detection

- Food detection

- Abnormal heat detection

OSS-ECAL specification

API Function

OSS-ECAL API functions are basically assumed to be function calls from a periodic Thread (TASK).

etSTS oD6T_1A02_READ_TEMP( stD6T_1A02_O* rlt )

The oD6T_1A02_READ_TEMP function is an API function that reads reference temperature data PTAT and pixel temperature data P0 and converts them to temperature.

– Step1 Send Command 0x4C (Read Temperature)

– Step2 Check frame validity: CRC

– Step3 Temperature conversion of reference temperature data PTAT (Min=-40.0°C, Max=+80.0°C)

– Step4 Temperature conversion of pixel temperature data P0 (Min=-40.0°C, Max=+80.0°C)

| Return value | etSTS | OSS-ECAL status code | |

| eSTS_FIN | Completed successfully | ||

| eSTS_ERR_MIN | Minimum temperature error (When rlt.pn[0] or rlt.ptat is the minimum temperature) | ||

| eSTS_ERR_MAX | Maximum temperature error (When rlt.pn[0] or rlt.ptat is the maximum temperature) | ||

| eSTS_ERR_DIAG | PEC CRC error | ||

| eSTS_ERR_I2C_OBJECT | I2C object selection error | ||

| eSTS_ERR_HAL_OTHERS_RUN | Other applications are running HAL | ||

| eSTS_ERR_HAL_I2C | HAL I2C Error | ||

| Parameter OUT | stD6T_1A02_O* rlt | Data received from D6T-1A-02 | |

| float32 pn[0] | Temperature conversion value of pixel temperature data P0 [°C] | ||

| float32 ptat | Temperature conversion value of reference temperature data PTAT [°C] |

HAL Support List

OSS-ECAL’s HAL support is as follows. Please note that even if the same HAL is used, different versions, MCUs, and development environments may not work together. The list is being expanded sequentially.

| Manufacturer | SDK/IDE Tool | HAL Name | Ver | HALNAME | Support |

|---|---|---|---|---|---|

| Arduino | Arduino IDE | Arduino | 1.8.6 | ARDUINO | – |

| Debian | – | GNU/Linux | 10.3 | Linux | X |

| Infineon | ModusToolbox | mtb-hal-cat1 | 2.4.3 | ModusToolbox | X |

| NXP | MCUXpresso SDK | SDK_2.x_EVKB-IMXRT1050 | 2.16 | iMXRT1051B1052B | X |

| Renesas | Synergy Software Package | HAL | 2.6.0 | SSP | X |

| STMicroelectronics | STM32Cube | STM32CubeF4 | V1.28.1 | STM32F4 | X |

Development environment

The MCU and development environment during OSS-ECAL development are as follows.

| HAL Name | Manufacturer | Board | MCU | IDE |

|---|---|---|---|---|

| Linux | BeagleBoard | BeagleBone Black | TI AM335x | – |

| ModusToolbox | Infineon | CY8CPROTO-063-BLE PSoC 6 BLE Prototyping Kit | CYBLE-416045-02 | ModusToolbox |

| iMXRT1051B1052B | NXP | IMXRT1050-EVKB | i.MX RT1050 | MCUXpresso IDE |

| SSP | Renesas | S7G2 SK | R7FS7G27H3A01CFC | e² studio for Renesas Synergy |

| STM32F4 | STMicroelectronics | STM32 Nucleo-64 boards | STM32F401RETx | STM32CubeIDE |

File Structure

| Folder* | File | Summary |

|---|---|---|

| D6T_1A02_HALNAME_VERSION/sample | sample.c (.cpp) | Sample application program |

| sample.h | Sample application header | |

| D6T_1A02_HALNAME_VERSION | oD6T_1A02.c (.cpp) | OSS-ECAL program for D6T-1A-02 |

| oD6T_1A02.h | OSS-ECAL header for D6T-1A-02 | |

| oss_ecal.h | OSS-ECAL common header | |

| user_setting.c (.cpp) | User configured constants and tables | |

| user_setting.h | User configuration Header | |

| oHAL_i2c_stm32f4.c | HAL Program for STM32Cube FW_F4 | |

| oHAL_i2c_stm32f4.h | HAL Header for STM32Cube FW_F4 | |

| readme.md | Readme | |

| OSS-ECAL Terms of Use.txt | OSS-ECAL Terms of Use |

* For HALNAME, please refer to HAL Support.

OSS-ECAL Download Contact

Please login before contacting us for downloads.

To register as a new user, click here.

Built-in How to

How to incorporate OSS-ECAL into user programs

How to incorporate multiple OSS-ECALs in a user program (same MCU function)

How to incorporate multiple OSS-ECALs in a user program (different MCU function)

How to incorporate multiple identical electronic components into a user program

How to reduce the impact on user programs by replacing electronic components

CAUTION

The sample version of OSS-ECAL is not intended to be used with Threads (Tasks) or interrupts of different priority. Please do not use it as in the example below.

Example: If each sensor is assigned to the same ADC group and the OSS-ECAL API is executed in processes with different priorities, correct values may not be obtained.

ADC Gr0 Ch0 Temperature sensor AD22100A 100ms cycle Thread (low priority) to take in temperature

ADC Gr0 Ch1 Pressure sensor MPX5999D Event interrupts (high priority) to take pressure